The priority task is to ensure the quality of construction

Quality has always been and remains one of Enter Engineering's top priorities. To carry out work in this direction, the company has a Quality Control and Assurance Department (QCA), whose specialists participate in the implementation of projects, inspect all stages of construction, interact with customers and suppliers, monitor compliance with the requirements and conditions of contractual obligations in terms of quality control.

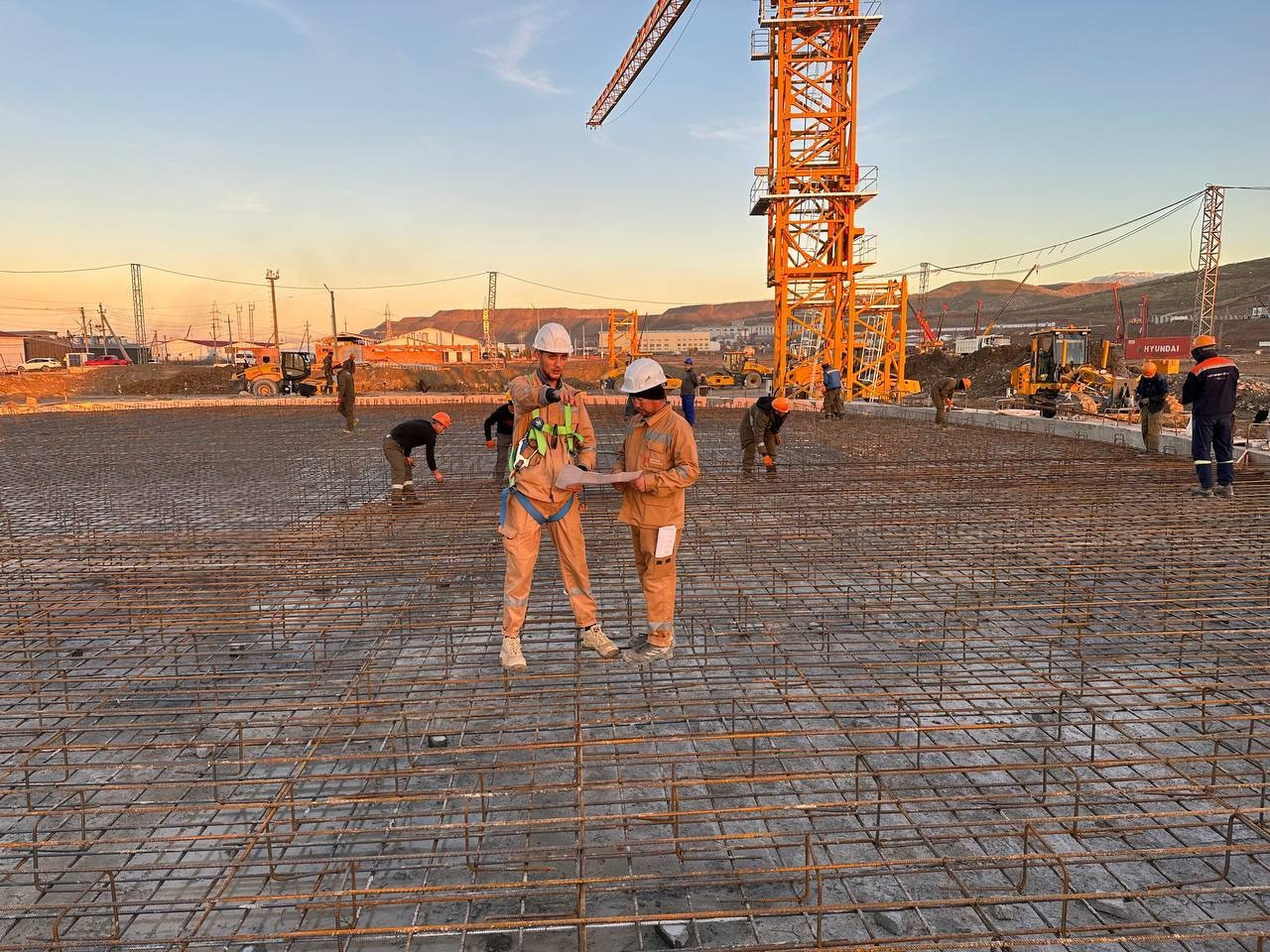

This fully applies to the construction of copper processing plant (CPP-3), where 30 employees of the QCA department group carry out inspections of all types and stages of construction and installation works (CIW), in accordance with the design decisions and the requirements of current regulations. Along with local workers, specialists from Kazakhstan, Russia, India and the Philippines work side by side here. The head of the department Kuvonchbek Shatiev told us about their activities:

— During the quality control of the CIW, our employees collect information about the work actually performed and assess the compliance of their results with the design characteristics of the facility, certain quality criteria. Dozens of facilities are currently being built on the CPP-3 project. Being in close cooperation with the engineering staff of the construction, including surveyors, we prepare and submit daily reports in electronic form on the current state of affairs for the customer service of AMMC. Subsequently, their representatives accept the site after an appropriate check. There are many tasks and they are solved around the clock, it is in this mode that all CIW is conducted today.

The group's employees prepare working documentation on the construction of the facility and technological maps of all production processes. The implementation of quality control is mandatory at all stages — from geodetic breakdown of axes to landscaping. Timely identification of errors and their elimination helps to prevent possible serious consequences during further operation of the facility.

As with other projects, here at CCP-3, we have been operating since the first day of construction. In case of detection of violations of work performance technologies or receipt of substandard raw materials, we issue appropriate instructions to responsible persons to eliminate them and monitor their execution. For example, this concerns the correct assembly of wiring diagrams of metal structures and equipment, laying of pipeline segments after completion of welding work.

Indeed, it is impossible to reflect all aspects of the tasks performed by the staff of the QCA department group in a small article, but they contribute daily to the implementation of the CCP-3 project. And we wish them success in their hard work and a wonderful mood!